Article

Obtain business insight with CLT's article

On July 3, 2025, the “2025 Smart Port Technology &

Industry Global Forum” was held at BPEX(Busan Port Int'l Exhibition & Convention Center) in Busan, jointly hosted by the Korea

Maritime Institute (KMI) and the International Association of Ports and Harbors

(IAPH). At this event, key industry leaders including Oscar Pernia, CTO of

NextPort.Ai, and Tommi Rinta-Kartano, Senior Manager at Kalmar, shared their

insights on future port technologies and operational strategies. Among the

notable presentations was “Integrated Smart Solutions for the Next-Generation

Port” by Lucy Lee, Senior Consultant at CyberLogitec (CLT), which is summarized

here.

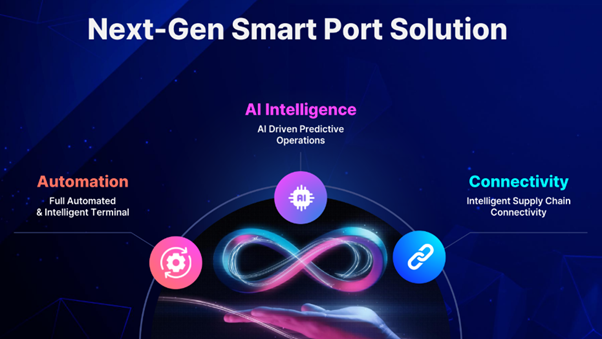

This session emphasized a crucial shift in focus: from

smart terminals to smart ports—and from current systems to next-generation

solutions. The term “next-generation” is often used in two contexts: when an

industry reaches the limit of its efficiency gains, or when rapid environmental

change renders existing systems obsolete. The port industry today faces both.

The Wave of Change in Port Operations

Ports around the world are confronting the dual

challenges of legacy system limitations and sweeping shifts in the global

environment. For example, data collected from multiple port authorities reveals

that fully automated terminals saw a 30% increase in throughput over the past

year, while conventional terminals experienced a 1.9% decrease. Profitability

for automated terminals also rose by 22%, demonstrating their operational and

financial superiority.

Meanwhile, the rapid upscaling of vessels continues.

Orders for ships exceeding 20,000 TEU are surging, and shipping alliances now

demand berth productivity equivalent to 31 cranes or more. Yet most individual

terminals—aside from a few mega-hubs—struggle to accommodate such scale,

resulting in transshipment cost burdens and weakened port competitiveness.

Berthing delays caused by infrastructure shortages further drive the need for

collaboration and integrated operations among terminals.

In this context, ports require an operational paradigm

that goes beyond legacy automation and isolated optimization. They must build a

connected digital ecosystem—centered on automation, intelligence, and interoperability.

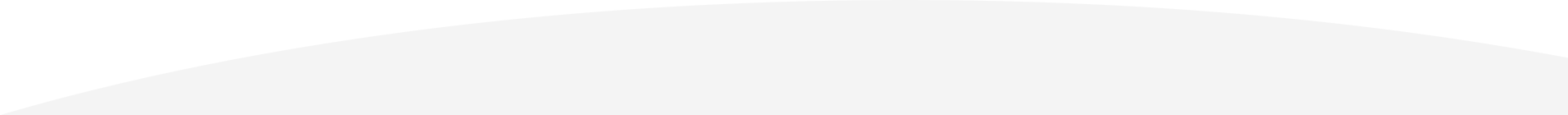

Core Technologies for a Digital Port Ecosystem

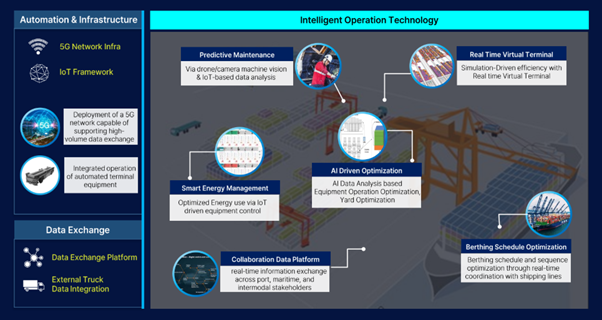

The technologies enabling this transformation fall

into two main categories: (1) automation and infrastructure technologies, and

(2) cognitive technologies that leverage the data generated by automation.

For instance, unmanned equipment movements are

transmitted via 5G to an IoT platform, which collects and analyzes data in real

time—enabling machine-based cognition rather than human-driven monitoring.

Equipment Automation and AMR Adoption

Significant advances have already been made in the

automation of terminal equipment, especially in horizontal transport. Traditional

manned vehicles have evolved into AGVs guided by transponders, and now into

autonomous mobile robots (AMRs) equipped with multi-sensors for environmental

awareness. A key benefit of AMRs is their ability to operate safely in mixed

traffic with manual equipment or external trucks, allowing for leapfrogged

deployment without intermediate infrastructure.

Currently, multiple terminals including Busan New Port

are conducting AMR pilot programs. Globally, many ports (including Busan) have

achieved full automation, while others like Ningbo and Shenzhen remain

partially automated. In some regions—especially India and Latin

America—retrofit automation is gaining traction, enabling ports to upgrade

existing equipment (e.g., remote STS and yard cranes, new horizontal transport

units) into fully automated systems.

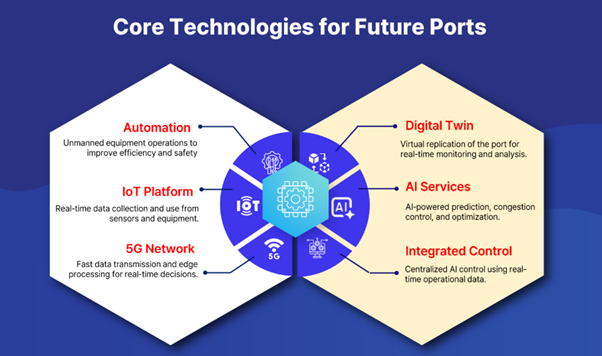

Such automation demands infrastructure support. As

shown in the referenced chart, more than 50 messages per second are exchanged

between terminal systems and equipment—not including inter-equipment

communication. This level of messaging requires high-speed, ultra-reliable

network infrastructure. Among available options, 5G outperforms Wi-Fi and wired

networks in mobility, coverage, and security, making it foundational for

digital port transformation.

Data-Driven Optimization with IoT and AI

5G-based communication enables real-time control

between automated systems and a centralized IoT platform, which comprises

rule-based control, event monitoring, analytics engines, and a data

center—laying the groundwork for data-driven decision-making.

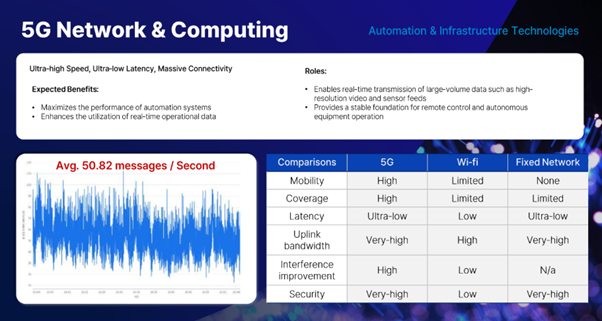

In port operations, bottlenecks at a single point

often impact the entire workflow. Data from a six-month operational analysis

revealed that a one-hour vessel delay reduced crane productivity by 8%, and a

two-hour delay by 14%. To address such inefficiencies, Digital Twin technology

replicates the physical port in a virtual space for real-time monitoring and

operational simulation. Combined with AI, Digital Twins can go beyond

visualization and support predictive simulations.

The Role of AI in Real-Time Optimization

Conventional TOS (Terminal Operating Systems) include

optimization logic, but these are based on fixed rules and limited

adaptability. Port operations are dynamic, with constant changes in equipment

status and work schedules—making real-time optimization difficult with

traditional systems. AI, however, excels in processing complex variables and

providing predictive insight.

While AI can analyze and forecast data, it still

requires execution through connected systems. This is where intelligent

integrated control systems come into play—serving as the neural network that

executes AI decisions across IoT platforms, automation equipment, and sensors.

Future Vision of Port Operations

In the future, terminals will be operated with fully

automated, 5G-connected equipment, enabling unmanned, around-the-clock

operations with minimal human intervention. AI-enabled platforms will optimize

container yard planning, berthing schedules, and maintenance forecasting.

Operators will be able to simulate operations via

virtual terminals, pre-test scenarios, and detect equipment failures in

advance. These AI-driven routines will create a predictive operations model,

shifting ports from reactive to proactive management.

While full automation is already maturing globally, AI-driven operations are still in early stages. CLT is currently conducting a proof-of-concept project that demonstrates its real-world potential.

A Real-World AI Case: Dwell Time Optimization

One global terminal (with over 10 million TEU annual

throughput) was facing critical yard congestion. CLT developed an AI service to

predict container dwell time and optimize yard placement.

1.

A machine learning model

forecasts dwell time based on container history.

2.

The AI system uses this

prediction and TOS operational factors to assign yard positions.

3.

These assignments feed into a

continuous learning loop—Plan → Execute → Learn → Replan—improving prediction

accuracy over time.

The POC aims to reduce unnecessary yard shifting by up

to 30%. The AI prediction model:

·

Avoids concentration in

specific blocks,

·

Simulates bottlenecks

pre-execution,

·

Provides a real-time dashboard

for anomaly detection and performance monitoring.

This AI service is offered as an add-on to existing

TOS systems and can also be applied in multimodal environments, where seamless

data exchange is essential across stakeholders like carriers, inland transport,

and customs. Instead of full system integration, CLT proposes a lightweight

data linkage model using asynchronous messaging and APIs—preserving system

independence while enabling intelligent ecosystem-level optimization.

The future of smart ports lies in creating a digital

ecosystem—built not only on automation and intelligence, but on scalable,

interoperable, and add-on solutions. An ecosystem thrives when participants are

organically connected in a self-reinforcing structure, sharing both technology

and value.

As a key player in the smart port ecosystem, CyberLogitec

is committed to continuous collaboration and value creation through

future-ready solutions.

Author:

Lucy Lee, Terminal Business Consultant, CyberLogitec

Copyright

© 2025 CyberLogitec. All rights reserved. Unauthorized reproduction or use is

prohibited.